Table of Contents:

This method involves melting the batteries to separate metallic fractions from non-metallic materials. It is often used to recover metals like nickel, cobalt, and copper, but it is less effective for lithium.

The pyrometallurgy method for lithium battery recycling is becoming less favored compared to other methods like hydrometallurgy and direct recycling. Pyrometallurgy is energy-intensive and can produce harmful emissions, making it less environmentally friendly. Advances in hydrometallurgical processes and direct recycling offer higher recovery rates of valuable materials with lower environmental impact and operational costs, leading to a shift towards these more sustainable and efficient methods. However, pyrometallurgy is still used for specific applications and materials recovery where it remains effective.

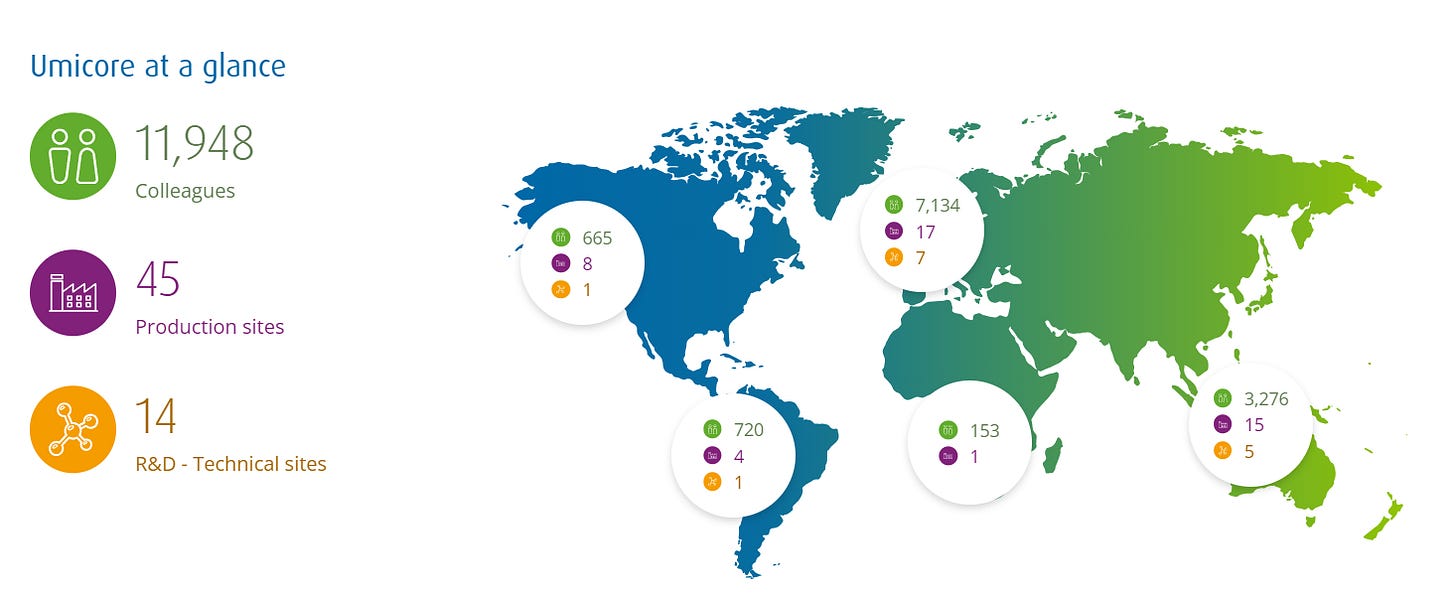

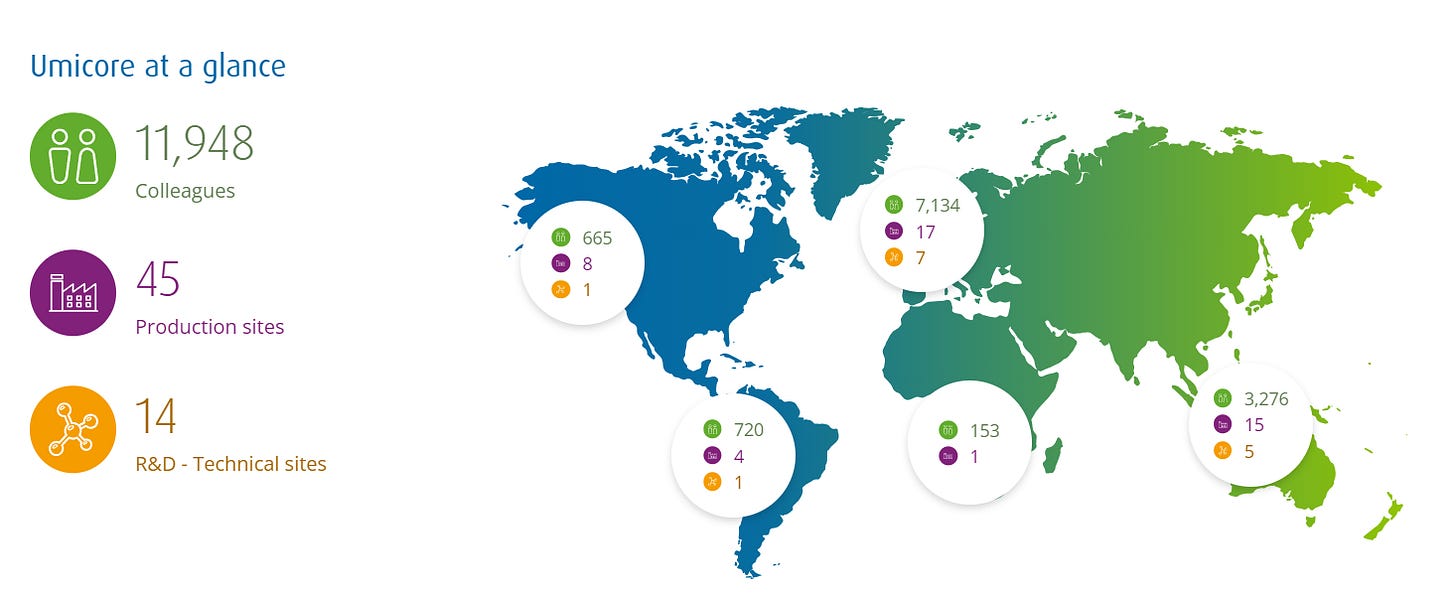

Umicore, headquartered in Brussels, Belgium, is a global leader in materials technology and recycling, dedicated to advancing sustainable practices across various industries. The company focuses on circular economy principles, notably in the recycling of precious metals and battery materials. Umicore’s comprehensive approach includes refining and recycling services that contribute to reducing electronic waste and promoting resource efficiency. With a significant emphasis on clean mobility and battery recycling, Umicore aims to be a pivotal player in the transition towards a more sustainable future.

Product

Umicore produces a wide range of products including battery materials for electric vehicles, catalysts for automotive emissions control, and materials for renewable energy applications. They also offer recycling services for precious and non-precious metals.

Battery Recycling Technique

Umicore utilizes a combination of pyrometallurgical and hydrometallurgical processes in their recycling operations. This integrated approach allows them to recover a variety of metals with high efficiency, supporting the sustainability of battery production and other industries. Their latest technology demonstrates recovery yields of over 95% for cobalt, copper and nickel from a wide variety of battery chemistries.

Use Cases

Figure 7: Umicore Global Strategy