Table of Contents:

Electrochemical recycling for batteries is a relatively novel method that uses electrochemical processes to reclaim valuable materials from spent batteries. It involves discharging processes to deplete residual charge and then using electrolysis to selectively recover specific metals such as lithium, cobalt, and nickel.

Neu Material is innovating in the field of battery recycling, focusing on lithium-iron-phosphate (LFP) batteries. Their patented technology provides a sustainable end-of-life solution, promoting a closed-loop recovery system that supports battery manufacturers, eMobility, and electronic waste recyclers by recovering battery-grade metals directly from production scrap and used batteries. Their processes meet emerging environmental, social, and governance (ESG) requirements and offer scalability validated by their Singapore facility.

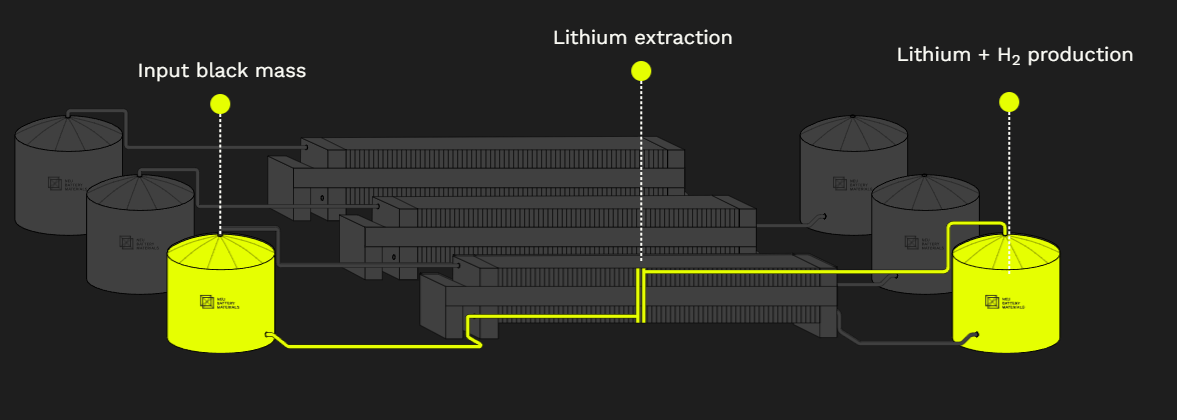

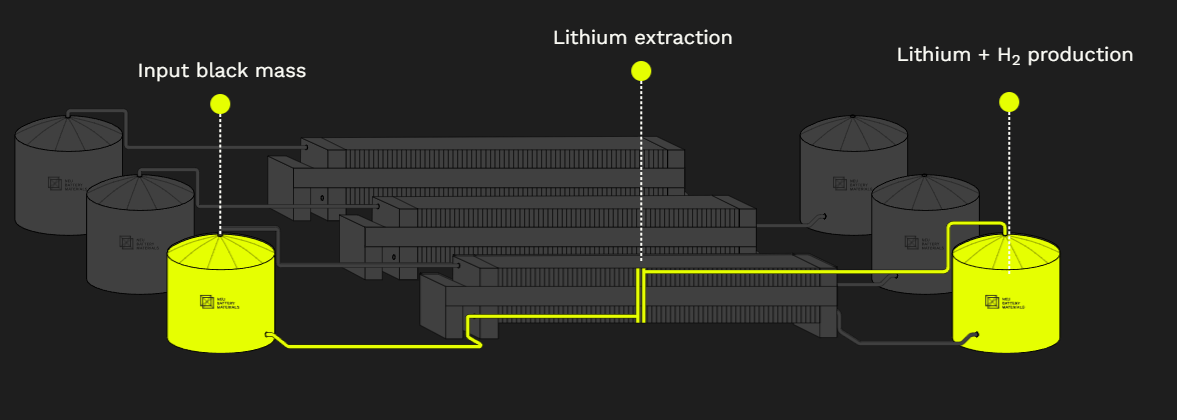

Product The main product is a patented, scalable electrochemical module designed for the recovery of critical metals from LFP batteries. This technology supports efficient recycling and is adaptable to various demands, providing a significant edge in battery-grade metal recovery.

Battery Recycling Technique Neu Material utilizes an advanced electrochemical process to extract critical metals from end-of-life LFP batteries. This method is not only environmentally friendly but also aligns with strict ESG standards by minimizing waste and bypassing the need for traditional, more pollutive recycling methods.

Use Cases

Figure 11: Redox targeting Electrochemical extraction

This method involves a membrane technology for direct lithium extraction (DLE) from brine resources, which is not traditional battery recycling but rather an innovative approach to enhancing the lithium supply chain necessary for battery production.